Extraction: Remove the Easy Water First

3/26/2019 (Permalink)

The most effective way to speed the drying process is to remove as much of the water in a liquid state as possible during the extraction phase of the restoration project. Poor extraction will significantly slow the drying process.

Extraction and evaporation are the only ways water can be removed from a wet structure. During the extraction process, liquid water is extracted, mopped, squeegeed or otherwise removed from the structure. This takes some energy, but not nearly as much as evaporation.

The most important factor in extraction is not how much water is removed, but how much water is left behind. It is important to remember that every drop of water left behind will add time to the drying project.

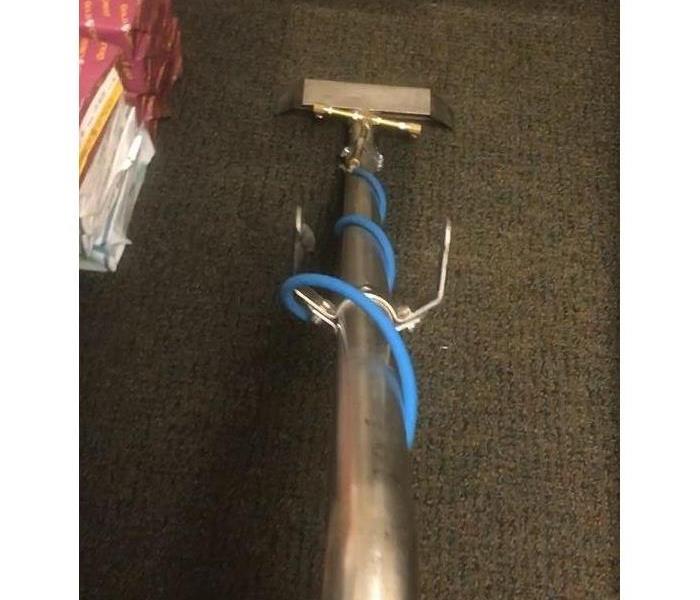

The two-step process for carpet and pad extraction:

- The primary goal of the initial extraction of the affected area is to contain further migration of the water within the structure. This step is accomplished using a light wand attached to either a portable or truck mounted extraction unit.

- The deep extraction process is accomplished by using a sealed or weighted extraction tool attached to either a portable or truck mounted extraction unit.

If deep extraction is not available, the carpet pad must be removed to prevent lengthy drying times. Otherwise, excess water will remain in the carpet underlay. This water must be removed through evaporation, which prolongs the drying process. It also increases the amount of equipment required to meet drying timelines and drastically increases the likelihood of secondary damage to the structure and its contents.

24/7 Emergency Service

24/7 Emergency Service